Recent Posts

Weird year, weird water filter maintenance?

Let’s be honest, 2020 was weird...but, the practice of maintaining your water filter is not.

Couple things about your water filter during the “winter downtime,” if that applies. First, make sure and run your system daily, even if you don’t have a current grow or are in between harvests.

It’s important for the health and longevity of your filters and membranes to avoid any still water, anywhere in your water filter system. Running your filter daily keeps the system bacteria and algae free, contaminants that can wreak havoc on not only the filters but the system itself.

However, if your system is already running slow don’t panic. If it’s cold outside the flow rate of reverse osmosis systems will always slow down, this is totally normal. If your system is clean and free of microbiological contamination, normal flow rates will return when it warms up.

Also, it never hurts to have backup filters around, just in case.

No matter what the season is, your filters should be changed regularly, so having a spare on hand makes that easier to remember.

Reference our Filter Replacement Schedule for any of the filters and membranes HydroLogic sells. When in doubt, start fresh!

Keep in mind, your housings may also need to be replaced every few years.

Temperature fluctuations and exposure to the elements can shorten the life of housings significantly. Refer to the system user manual to make sure the filter housings are always in top shape. Tossed it out? Head to our website, we’ve got a copy to download on your system’s product page under the “resources” tab.

Any questions? We are ready to help you.

And finally, warm Holiday Greetings from all of us at HydroLogic and HyperLogic Professional Filtration Systems. As we look back on this remarkable year, the good, the bad, and everything in between, we just wanted to take a moment to express how grateful we are for you, our customers. You are the best, all of you, and we really mean that.

Looking forward to a better, brighter, and less weird 2021!

Hydroponic Dechlorination for Stronger, Healthier Plants

How to Dechlorinate Tap Water for Hydroponics

porous material filled with

micro-fissures that capture and contain

numerous chemicals including

chlorine and chloramines

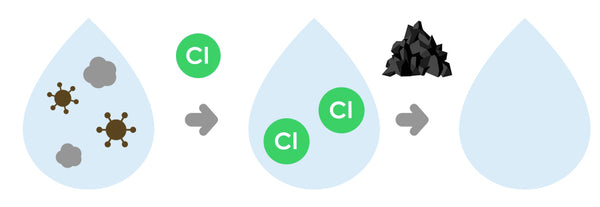

What is the best way to dechlorinate water for use in a hydroponic garden? Most people agree, the easiest and most efficient way is to simply purchase a dechlorination water filter. Dechlorinator filters remove the chemical before the water enters the hydroponic system.

These filters contain activated carbon, a porous material that condenses a large volume of surface area into a very small amount of physical material. A single gram of activated carbon is equal to up to 32,000 square feet of molecule-grabbing surface area! Millions of water treatment systems around the world use activated carbon for a number of reasons, all to ensure proper and safe water quality.

There are other methods to remove chlorine from tap water, such as:

- Leaving the water out in the sun

- “Bubbling” where forced aeration of the water oxidizes the chlorine over time

- Dechlorination tablets typically made of ascorbic acid, neutralize chlorine relatively quickly

- Even boiling the water works if no other options are available

However, carbon filters are the only method that doesn’t require extra time or the need for a holding tank.

Why Dechlorinate Tap Water for Hydroponics?

With hydroponics, there are two big issues with chlorine and chloramine treated water that growers need to take very seriously if they wish to achieve consistent, high quality yields. The first, if too much chlorine is present in water used for hydroponic farming, plant leaves will first turn yellow, then brown, and eventually the plant will die. This is called “chlorine toxicity”.

With hydroponics, there are two big issues with chlorine and chloramine treated water that growers need to take very seriously if they wish to achieve consistent, high quality yields. The first, if too much chlorine is present in water used for hydroponic farming, plant leaves will first turn yellow, then brown, and eventually the plant will die. This is called “chlorine toxicity”.

The second problem is when using helpful microorganisms such as beneficial bacteria and fungi, all must have chlorine-free water to survive and flourish. When utilized correctly, these tiny creatures help protect roots, increase nutrient uptake and directly affect the quality of and size of yields. Killing bacteria is a good idea for humans, but not necessarily when it comes to water for plants. And, since nutrient solutions are typically calibrated with purified water, the best way to maximize their benefits is to make sure water is chlorine and chloramine-free.

Why Do Commercial Hydroponic Farms Dechlorinate Their Water?

Commercial hydroponic facilities dechlorinate water for a number of reasons that the hobbyist grower can learn from. If a reverse osmosis (RO) filter is used (as we mentioned before, hydroponic nutrient solutions are calibrated with RO water) chlorine and chloramines must be removed prior to the water hitting the filter membrane. Membranes are dense, porous layers of materials that are easily damaged by both chemicals. Without proper pre-filtration to dechlorinate incoming water, the expense to keep functional membranes in place would be enormous.

Commercial hydroponics operations remove chlorine and chloramine for another very simple reason: minimizing troubleshooting. This is known as “controlling all inputs” which enables serious growers to minimize downtime by maintaining consistency by reducing any variables to a bare minimum. Of course, all of the root supporting benefits of dechlorinated water still apply, even on an industrial scale.

Chlorine In Tap Water

Why is chlorine added to public sources of water? The simple answer is, it kills the bad microorganisms that could make water dangerous for humans to consume. Drinking water in North America is regulated for safety, and is either treated with chlorine, or less commonly a chemical variation of chlorine called chloramine.

The two compounds are very similar; chloramine is essentially chlorine and ammonia, bonded on a molecular level. This slight molecular difference allows the antimicrobial function of the compound to reach long distances, without a loss of potency.

Consequently, it’s more difficult to remove chloramines from tap water and require either reverse osmosis filtration or special filters like the HydroLogic Chlorashield. At the regulated amount of 4 ppm (parts per million) both chlorine and chloramines are considered safe for human consumption.

Which Home Water Filtration System to choose?

Buying a new drinking water filtration system for your home is an important decision. Everyone deserves reliably clean water and, spoiler alert, reverse osmosis is still the best and most efficient way to ensure confidence that your water is safe to consume. But with all the different kinds of water filtration methods, makes and models to choose from, understanding which system best suits your specific needs can be tricky. In this article, we try and break down the most important information you need to know to make the best decision.

Buying a new drinking water filtration system for your home is an important decision. Everyone deserves reliably clean water and, spoiler alert, reverse osmosis is still the best and most efficient way to ensure confidence that your water is safe to consume. But with all the different kinds of water filtration methods, makes and models to choose from, understanding which system best suits your specific needs can be tricky. In this article, we try and break down the most important information you need to know to make the best decision.

How safe is your drinking water?

According to the World Health Organization about half a million deaths each year are attributed to poor quality drinking water, worldwide. However, municipal city water in the USA is considered relatively safe. In 2016, over 90% of all systems across the country were in compliance with standards set forth by the federal Environmental Protection Agency. Of course, this means that 1 in every 10 municipalities was failing, and it is likely that year to year, the locations of these violations will change.

Interested in knowing more about your local water? The Environmental Working Group (EWG) has a simple online tap water contamination check based on your zipcode. For specific location testing, you can order mail-in kits like these from SimpleLab™.

Interested in knowing more about your local water? The Environmental Working Group (EWG) has a simple online tap water contamination check based on your zipcode. For specific location testing, you can order mail-in kits like these from SimpleLab™.

Biological contaminants are typically held in check by the microbicides chlorine and chloramine. However, their effectiveness is contingent on chemical potency traveling all the way to the tap, so the method is not foolproof.

Toxic substances like lead and arsenic can also make their way to the end user, and the difficult truth is there are over a million miles of lead pipe feeding drinking water to Americans. In Flint, Michigan, one of the worst mass lead poisoning cases in modern history occurred when officials switched water sources without considering how the new water’s chemistry would affect the biofilm holding back lead particles that had accumulated inside the piping. The result was disastrous and will have human cost repercussions lasting many years.

For the 13 million US homes using a well for drinking water, results are less predictable. Since there is no EPA regulation on wells, owners are responsible for the safety of their water. Well water is generally considered safe, but with absence of municipal microbicides, it is important to test water quality regularly, as seasons, temperature and other factors can alter water chemistry throughout the year. The most trusted and reliable way to ensure well or municipal water is clean and ready to drink is to run the source water through a reverse osmosis filter.

What is Reverse Osmosis?

Simply put, reverse osmosis water filters (called “membranes”) are made of a very dense material with microscopic pores (about 0.0001 micron) that filter out anything larger than a water molecule (also about 0.0001 micron). This can include, but is not limited to, toxic metals such as lead, mercury and arsenic, sediment, rust and fluoride, as well as biological contaminants such as bacteria and viruses. It is even possible to desalinate (remove the salt) from saltwater, although a necessary increase in membrane density requires a tremendous amount of energy and pressure to separate water and salt molecules, which are also very small (about 0.0007 micron).

Which is the best water filtration method?

Comparing Reverse Osmosis to other popular filtration methods is important to understanding how to make the right choice when shopping around. When properly maintained, a reverse osmosis system is, generally speaking, the most effective of all water filters, but that doesn’t mean there aren’t any other options. Here is a list of other methods that remain popular for various reasons.

Comparing Reverse Osmosis to other popular filtration methods is important to understanding how to make the right choice when shopping around. When properly maintained, a reverse osmosis system is, generally speaking, the most effective of all water filters, but that doesn’t mean there aren’t any other options. Here is a list of other methods that remain popular for various reasons.

- Ultraviolet sterilizers: These systems use UV-C light to disrupt the DNA in biological organisms, and have become a standard for non-chemical disinfection across the globe. These systems have no filters to change but do require annual replacement of the UV-C bulb. The major downside of UV sterilizers is that they do not have any effect on non-biological contaminants such as arsenic or lead, so they are typically used as a pre-treatment or post-treatment method for reverse osmosis systems.

- Ceramic filters: These filters, when produced at sufficient quality standards, are effective at managing biological contaminants. However, they do not remove chemical contaminants, and require a separate filtration method, such as reverse osmosis, to do so.

- Carbon filters: While carbon filters can improve the quality of water, especially the taste and smell, reverse osmosis filters remove much, much smaller particles from the water supply. While these filters are useful for removing chlorine and chloramines, a carbon filter alone should only be used if taste improvement (and not safety) is the only desired outcome.

- Distillation filter: These filters use a heating element to boil the water, catching the purified steam. Like reverse osmosis water, captured steam is essentially pure and contamination-free. The downside to these filters is that they are slow and energy intensive. Also, like reverse osmosis, they strip away the good ions such as calcium and magnesium, which are both essential to human health and give water a pleasing flavor.

- Deionization filters: These filters use resins to exchange ions holding a positive or negative charge (such as iron or silica, respectively) with hydrogen and hydroxyl, thus forming pure water which has no charge. This method works well as a “final pass” to remove all minerals from water but does not remove biological contaminants.

If the goal is complete filtration at a reasonable price, the clear winner is reverse osmosis. The only other method that comes close is distillation, but it is expensive, slow, and dependent on an external power source.

Drawbacks to Reverse Osmosis

The first is, all RO systems produce varying amounts of wastewater. Contaminants that are blocked from passing through the reverse osmosis membrane are either trapped inside the filter’s porous material or are flushed down the drain in a wastewater stream. Typically speaking, most under the counter systems produce 4 parts wastewater to 1 part purified water. With more efficient systems, the ratio is more like 3 to 1. RO wastewater, while not drinkable, can be used for a number of things such as washing dishes, sinks or toilets. And while it’s not advised to use wastewater to water plants grown for food or medicinal purposes, you can certainly water your flower garden with it!

The other drawback to drinking reverse osmosis water is that healthy minerals, such as calcium and magnesium, have been removed. The only difference between distilled water and reverse osmosis water is *how* those minerals (and other impurities) were removed, they are indeed essentially the same thing.

What is Spring Water?

Spring water or “mineral water” became popular through the idea that beneficial minerals exist in natural drinking water, which is true. Premium drinking water systems solve this problem by adding a “remineralization” phase to the filtration process, where minute amounts of calcium and magnesium, both essential to human health, are

Spring water or “mineral water” became popular through the idea that beneficial minerals exist in natural drinking water, which is true. Premium drinking water systems solve this problem by adding a “remineralization” phase to the filtration process, where minute amounts of calcium and magnesium, both essential to human health, are

added back into the water, which helps balance the water’s pH as well as improve the taste.

HydroLogic is proud to offer one of the finest and most affordable under the sink reverse osmosis systems available, the ecospring. The ecospring offers premium features such as remineralization, fast tank refills and a 3 to 1 wastewater to purified water ratio. Once the system is set up, changing filters takes seconds and requires no tools. And of course, one of the best reasons to buy your own pure water home drinking system: No more plastic bottles!

Drain or Reclaim?

How to Prepare for Impending Water Regulations

As regulations on hydroponic cultivation facilities come into shape, municipalities will continue to further investigate power, water, and nutrient use in the industry. Working with experienced engineers and consultants, sourcing the optimal equipment, and scrutinizing all essential inputs will ensure the most efficient production facility as possible. Many operation managers and municipalities have not yet considered the regulations controlling water usage and wastewater discharge. These regulations would impact producers dramatically and may even put some out of business due to higher operating costs and competition.

As the industry evolves, certain water regulations put in place could jeopardize an existing operation’s legality. As drought-stricken states like California, Nevada, and Arizona develop regulations on hydroponic cultivation operations, water volume usage and discharge will be something municipalities in those states will closely consider, if they haven’t already.

The two main water regulations on hydroponic cultivation facilities concern volume usage limitations and wastewater quality regulations. If a facility is regulated on water quality that can be discharged into the sewer, the agricultural runoff water must be processed with a variety of methods. These methods include:

- Filtration and recycling

- Off-site shipping

- On-site evaporation

- Evaporation ponds

- Dilution, and/or

- Processing through artificial wetlands

- Cut back on planned or operational plant production

- Install a recirculating hydroponic system

- Filter and reclaim runoff water for irrigation, or

- Do all three

The potential regulations create an incentive for many producers to seek ways to create a facility with “Zero Liquid Discharge,” however there are many associated challenges with building these types of systems.

Moving toward Zero Liquid Discharge means moving away from the traditional horticultural method of relying on “drain to waste” systems. The runoff from a drain to waste system is sent literally down the drain into the sewer system, which is of main concern for regulators.

A closed loop system is possible, however, input costs would be extremely high compared to a traditional efficient drain to waste system. A system that can recycle all runoff water on a large scale must be extremely specialized and the facility must be engineered around this concept. Closed loop systems require constant water testing and at some point require some sort of wastewater discharge, which then may also need to be processed further.

As an alternative, processing runoff water on-site for recycling and volume reduction is used by a variety of industrial facilities. Using reverse osmosis (RO) to filter wastewater is the least energy intensive and most economically sustainable way to remove dissolved solids from runoff water, however, this application produces concentrated wastewater that must be trucked off-site or evaporated.

Yet another option is a wastewater evaporator, which is extremely energy intensive and will produce waste in the form of sludge/solid that must still be trucked off-site.

Integrating RO and distillation/evaporation is the most economical way to truly achieve Zero Liquid Discharge, however, it is still extremely expensive. These systems are most efficient when treating large volumes of water, which makes them the most suitable option for extremely large commercial/industrial operations. This means that most facilities need to take the approach of saving water by altering their growing methods to use as little water as possible, and then minimizing the volume to be shipped off site for treatment.

While the above methods are all industrial solutions to treating agricultural runoff water, there are a few biological solutions as well. The main contaminants in the runoff water must be analyzed and in many cases, this water source can be treated with artificial wetlands. In an artificial wetland, water with dissolved nutrients enters into the system and a variety of bacteria, plants, and other organisms convert the nitrogen-based fertilizers into actual biomass. This is a great solution for any facility that has proper permits and land to do this. The problem is that these types of systems do not work in an industrial area where there isn’t land available.

What is the answer for facilities dealing with water volume usage limitations?

Many facilities dealing with daily limits on water volume usage filter runoff water (including nutrient runoff and condensate produced by any climate control equipment) to reuse for irrigation. These facilities typically use reverse osmosis to purify nutrient runoff water prior to irrigation. Condensate runoff does not need to be treated with reverse osmosis, and can be reclaimed using alternative treatment methods.

What about drain water discharge regulations?

Facilities dealing with concentrated water discharge regulations usually must truck all nutrient runoff water off site. Many operations pay for this water to be taken away by the gallon. However, one way to minimize the liquid discharge of the facility is to use RO to further concentrate the contaminants in the wastewater streams so that there is a smaller volume of wastewater that needs to be disposed of less frequently.

Conclusion

While regulations will make life difficult for hydroponic cultivation facilities, we need to understand why these are being put into effect. Freshwater is a precious resource and must be conserved. High levels of nutrients being discharged into the environment have dramatic negative impacts, which can be seen from industrial agricultural practices. Wastewater treatment plants may have difficulty treating the high volume of nutrient-rich water from these hydroponic facilities and regulation must take this into account to maintain proper infrastructure.

Whether your cultivation facility is operational or a new build, asking your municipality about current or impending water regulations will become crucial to maintaining a sustainable and competitive operation. Not dealing with water regulations yet? They are likely to come—especially if you’re in an area where water is a scarce resource. Consider your options wisely.

Kombucha and Reverse Osmosis Water

In every production industry, taking the guesswork out of troubleshooting is equal to money in the bank. When it comes to the competitive world of kombucha production, having full control over water chemistry is one of the most important investments a company can make. For Aina Kombucha, starting with a pure water base using HydroLogic reverse osmosis filters was essential to the science, engineering and, ultimately, the profitability of their product.

SCOBY thrives in reserve osmosis water

The most important component of producing excellent kombucha on a commercial scale is the health of the SCOBY. Since not everyone is familiar with that term, the world SCOBY (an aquatic, gelatinous, cellulose-based biofilm) stands for Symbiotic Culture Of Bacteria and Yeast. Essentially, the SCOBY is responsible for anaerobically metabolizing sugars into that zingy, fresh taste that makes kombucha and other healthy probiotic drinks so popular. Here’s the upshot on creating and maintaining a happy, productive SCOBY: It LOVES pure water.

The fastest, most efficient and most economical way to make pure water is with Hydrologic's reverse osmosis filter. Water chemistry variables are the sworn enemy of kombucha production. Chlorinated tap water is, by design, supposed to kill things like bacteria and yeast. Water with any kind of toxicity or parasites should be avoided, period. Even mineral content can damage a SCOBY, over time. In order to be batch-consistent and predictable in output, SCOBYs need pure, clean water (and of course, a lot of sugar to digest).

Aina and Hydrologic: Two Great Tastes That Go Great Together

Aina Organic Kombucha, a family owned, small batch and totally delicious Kombucha company, made the leap to HydroLogic reverse osmosis filtration systems to ensure their SCOBY investments can thrive in the best conditions possible. What separates Aina from the rest of the kombucha pack, is their exquisite attention to detail, locally sourced organic ingredients and dedication to the health and happiness of their SCOBY crew!

Hope you get a chance to try this delicious beverage! And remember it was made with PURE water.

For information Aina Kombucha on Instagram.

Water Filtration Story: Puerto Rico after Hurricane Maria

ACT I: No Clean Water

Puerto Rico’s water has been on our minds a lot and for a good reason. As the 2018 hurricane season is about to ramp up, the island is still recovering from the aftereffects of Maria, one of the worst disasters in Puerto Rico’s recorded history. Even today, there are entire communities still without power or fresh water. While some consider the government’s response to Maria as inconsistent and coming up short, it’s been nothing short of amazing how many individuals and companies stepped in to do what they can to help. Some incredible examples include Operation Agua, LifeStraw and WaterStep, all raising money to provide clean water.

Puerto Rico’s water has been on our minds a lot and for a good reason. As the 2018 hurricane season is about to ramp up, the island is still recovering from the aftereffects of Maria, one of the worst disasters in Puerto Rico’s recorded history. Even today, there are entire communities still without power or fresh water. While some consider the government’s response to Maria as inconsistent and coming up short, it’s been nothing short of amazing how many individuals and companies stepped in to do what they can to help. Some incredible examples include Operation Agua, LifeStraw and WaterStep, all raising money to provide clean water.

When hurricane Maria hit, several months ago over half of the island was left without access to drinkable water. A week later that number barely dropped and even after months following the devastation, 35% of Puerto Rico’s 3.4 million citizens still did not have a source of clean drinking water. The logistics are daunting: Shipping as much water as needed would be next to impossible, and mass scale desalination, while currently under serious consideration, will take years to implement. The only way to make the impossible happen is to filter and re-use whatever water is readily available.

When hurricane Maria hit, several months ago over half of the island was left without access to drinkable water. A week later that number barely dropped and even after months following the devastation, 35% of Puerto Rico’s 3.4 million citizens still did not have a source of clean drinking water. The logistics are daunting: Shipping as much water as needed would be next to impossible, and mass scale desalination, while currently under serious consideration, will take years to implement. The only way to make the impossible happen is to filter and re-use whatever water is readily available.

ACT II: Water Filtration

Kelly Hassberger and Charlie Peterson, owners of the juice and healthy food bar Degree 18 in Puerto Rico immediately understood what needed to be done and contacted us with a great idea: If HydroLogic could donate the equipment to create fresh water, they would install it, maintain it and make 1000 gallons a day available to the public at no cost. We knew the perfect system for the job, our best-selling workhorse of all time, the Evolution-RO™. Using rain, river and municipal source water, Kelly and Charlie were able to install the Evolution, set up holding tanks and supply the needed power to deliver as promised. They are currently still serving as many people a day as possible and have plans to expand their clean water operations to many different parts of the island. Sometimes, it takes a community to do make things happen, and HydroLogic is proud to have played a key role in this fantastic humanitarian effort.

Using rain, river and municipal source water, Kelly and Charlie were able to install the Evolution, set up holding tanks and supply the needed power to deliver as promised. They are currently still serving as many people a day as possible and have plans to expand their clean water operations to many different parts of the island. Sometimes, it takes a community to do make things happen, and HydroLogic is proud to have played a key role in this fantastic humanitarian effort.

Is Tap Water Okay for Hydroponics?

Water Quality Report—First Things First

The answer is dependent on your water chemistry. Tap water quality fluctuates greatly throughout a region, over the seasons, and can even vary from site to site. If you are on city water, contact your municipality and they can provide you with free water reports, usually these reports can be found online. If you are on well water, you will need to test the water yourself. This can be done through a local lab, with mail-in kits like these from SimpleLab™, or by working with Arvum Plant Labs.

Understanding the source water chemistry helps hydroponic growers decide whether or not using a water filtration system would be beneficial.

Water Contaminant FAQs

What is in tap water?

Why is chlorine in tap water?

What are chloramines?

How do you remove chloramines?

What is water hardness?

Water hardness is made up of calcium and magnesium dissolved in water and is the key cause of most water problems in hydroponic facilities. High levels of hardness in untreated water lock out key nutrients to plants and also form scale on equipment and tubing. Calcium and magnesium are often the most abundant hardness minerals in tap water. The most typical form of these minerals in water is calcium carbonate and magnesium carbonate, and is often measured in grains per gallon (gpg). The molecules of these compounds found in untreated water are far too large and immobile to be absorbed efficiently by the root systems and transported to where the plant needs them.

For hydroponics, hardness is best removed by a reverse osmosis system which will reduce hardness by over 95%. While a softener will also remove hardness, it will substitute sodium for the hardness, making it difficult to grow plants with water that contains high levels of sodium.

Is there fluoride in tap water?

Is fluoride bad for plants?

Do volatile organic compounds (VOCs) affect plants?

How does iron or sulfur affect water and hydroponic equipment?

How does bacteria affect groundwater quality?

How do nitrates affect plant growth?

How does pH affect plant growth?

Condensate Water for Irrigation: Worth the Risk?

With the explosion of opportunities for indoor and greenhouse hydroponic facilities, the focus on efficiency becomes increasingly important. Sustainability is the feature that will ensure that your indoor or greenhouse grow stays viable and profitable for years to come, which is why it’s important to have progressive practices in place as early as possible. Water is a key resource that can be dramatically conserved and optimized when it’s properly managed, so developing a plan is critical for the overall success of your grow.

As regulation for commercial cultivation operations and competition increases, growers are becoming more sophisticated by sharpening their horticultural skills and refining the technology in their facilities. Grow room design is becoming more data and science driven. Many indoor cultivators are opting for sealed rooms and closed loop systems with every input stringently monitored and criticized including all water resources.

Water sources for both indoor and greenhouse grows are typically provided either by the city or from well water, and the quality of either type of water can vary dramatically. Most cases require a water treatment plan. In the majority of large scale commercial hydroponic facilities, dehumidification and air conditioning are an absolute necessity. Both of these systems have a constant flow of condensate water which is normally lost down the drain as waste water. In an effort to conserve water, many growers consider using this water for agriculture. This makes a lot of sense as the water, in theory, is distilled from the air and should be relatively clean. In order to determine the true viability of this water source, it’s important to analyze its quality and the HVAC system that is producing it.

Not all climate control equipment is built with the same materials, which means that the condensate water quality can vary depending on the individual system. Time is also a factor, as the internal parts age and collect dirt and bacteria and affect the water quality in different ways.

Suspended Solids

Dust and other suspended solids that collect inside air handlers, dehumidifiers, and condensate lines accumulates in condensate water, becoming a major issue. This debris will vary with the age and make of the climate control system, and how clean or dirty the indoor grow area is, but it is necessary to be aware of these contaminants and take measures to reduce them.

Chemical Quality

Taking a look at the quality of the water in terms of minerals is a bit complicated. Upon testing water with a traditional TDS meter, you will hopefully notice that the discharge from the unit reads very low in TDS (ppm). This makes sense, as this is distilled water vapor from the air. However, just because the TDS meter reads 0 ppm does not mean that there are no minerals or harmful substances in the water. The internal coils in air handlers, dehumidifiers and other mechanisms contain heavy metals that will leach into the condensate water. Some of these specific metals are considered harmful in very low quantities. The EPA has limits for certain contaminants. Lead, for example, has a toxicity rate of 0.015 ppm and would be undetectable by a TDS meter yet still poses a risk. Copper has a maximum allowable level of 1.0 ppm and zinc is 5.0 ppm. These levels may seem low but they can be harmful nonetheless. Although heavy metals like this would likely not have immediate effects on most crops, it can bio-accumulate in the mass of the plant material or in the growing media which would certainly affect overall quality. Those wanting to grow fully organic and as pure a crop as possible, these heavy metals should be totally absent in the irrigation water.

pH Levels

Another consideration is the pH of the condensate water. Typically, the overall mineral content is very low and therefore the water tends to absorb atmospheric CO2 making the water very acidic. The pH level can test below 5.0 points. This means that the water is corrosive and will absorb metals and other contaminants depending on what it comes in contact with in the facility. Adding a buffer and re-mineralizing the water will resolve the pH issue.

Biological Contaminants

Biosecurity in high tech grows is also another major issue when it comes to using condensate water. As any experienced grower knows, harmful pathogens can become a huge issue and take lots of effort to track down and ultimately control. Precautions should be taken to ensure that pathogens are not introduced into condensate water destined for reuse by plants. The internal coils and other components of air conditioning and dehumidifier systems are ideal environments to harbor numerous species of bacteria. Observing untreated water in condensate storage tanks, you will see slime and other species take hold and grow. Not all bacteria is harmful, but this type of environment acts as a breeding ground for harmful species. Legionella is an airborne bacteria responsible for outbreaks among humans and has been traced to condensate water. Treating this water involves the use of ultraviolet sterilization or chlorination.

Using Condensate Runoff from A/C and Dehumidifier Units for Agriculture

Due to the potentially harmful qualities of condensate water as outlined above, the cost of treating this water is minimal compared to the potential damage caused by using raw condensate water. To protect the longevity and safety of your indoor or greenhouse grow operation, it makes sense to treat the water for each of these problems in order to prevent a much larger problem later. There are turnkey solutions available to the modern grower that can address all of the issues associated with untreated condensate water. These solutions offer a relatively economical insurance policy to protect your valuable investment.

HydroLogic has a four stage filtration solution for condensate purification called the ARCS.

Hydro Filter Flow Rate Testing: How do we stack up?

One of the hallmarks of a successful company is to “under promise, and over deliver.” We take that philosophy seriously, which not only makes customers very happy with our performance, but also demonstrates the clear difference between our products and anyone else’s. Grozine put one of our best sellers to task against a competitor’s unit, rated at a substantially higher GPD. The results were, well, you should see for yourself! Head on over to Grozine and check it out. Evolution-RO™ vs Ideal H2O 1200